Flush Grid Modular Belt vs Flat Top Modular Belt: Choosing the Right Conveyor Solution for Your Industry

Apr. 22, 2025

In the evolving landscape of industrial automation, selecting the appropriate conveyor belt is crucial for operational efficiency. Among the prevalent choices are Flush Grid Modular Belts and Flat Top Modular Belts. Understanding their differences, advantages, and ideal applications can guide industries in making informed decisions.

Understanding the Basics

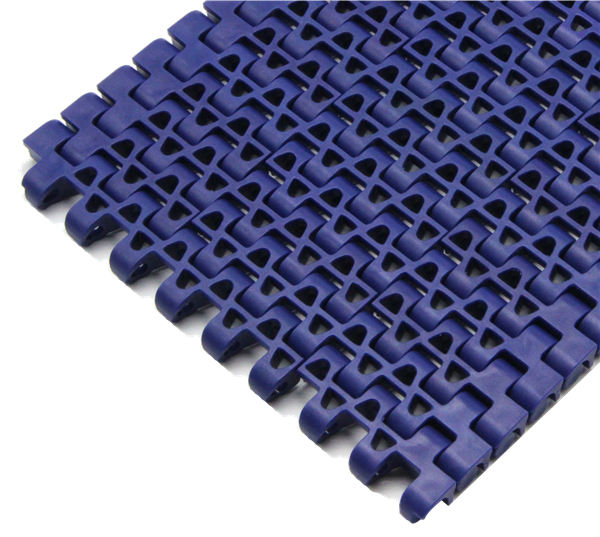

Flush Grid Modular Belts

Flush Grid Modular Belts are characterized by their open surface design, featuring openings that facilitate air and liquid flow. This design is particularly beneficial in applications requiring drainage or airflow, such as cooling or washing processes. Commonly utilized in the food industry, these belts are ideal for transporting products like meat, poultry, seafood, and baked goods, where hygiene and cleanliness are paramount.

Flat Top Modular Belts

Flat Top Modular Belts, on the other hand, offer a smooth, continuous surface without openings. This design ensures stable and uniform product handling, making them suitable for applications where product stability is critical. Industries such as packaging, electronics, and pharmaceuticals often prefer Flat Top Belts for their ability to handle delicate or small items without the risk of them falling through gaps.

Comparative Analysis: Flush Grid vs Flat Top Modular Belts

Hygiene and Cleanability

Flush Grid Belts: The open design allows for easy cleaning and quick drying, reducing the risk of bacterial growth. This makes them ideal for food processing environments where sanitation is crucial.

Flat Top Belts: While they provide a smooth surface, cleaning can be more challenging due to the lack of drainage, potentially leading to residue buildup if not maintained properly.

Product Stability

Flush Grid Belts: The openings can pose challenges for small or unstable items, which might get caught or fall through the gaps.

Flat Top Belts: Their continuous surface ensures better support for a wide range of products, enhancing stability during transportation.

Airflow and Drainage

Flush Grid Belts: Designed for optimal airflow and liquid drainage, making them suitable for cooling, drying, or washing applications.

Flat Top Belts: Limited in this aspect due to their solid surface, which can hinder processes requiring ventilation or drainage.

Maintenance and Durability

Flush Grid Belts: The modular design allows for easy replacement of damaged sections, reducing downtime. Materials like PP and POM offer resistance to wear and chemicals.

Flat Top Belts: Similarly modular, they are easy to maintain and are constructed from durable materials suitable for various industrial environments.

Pros and Cons at a Glance

Flush Grid Modular Belts

Pros:

Excellent for applications requiring drainage and airflow.

Easy to clean, promoting hygiene.

Modular design allows for easy maintenance.

Cons:

Not ideal for small or unstable products.

Openings can allow debris to accumulate if not cleaned regularly.

Flat Top Modular Belts

Pros:

Provides stable surface for a variety of products.

Suitable for delicate or small items.

Durable and easy to maintain.

Cons:

Limited airflow and drainage capabilities.

May require more effort to clean thoroughly.

Making the Right Choice

When deciding between Flush Grid vs Flat Top Modular Belt, consider the specific needs of your operation:

Choose Flush Grid Belts if your process involves washing, cooling, or requires high levels of sanitation, especially in the food industry.

Opt for Flat Top Belts if you need a stable surface for transporting small, delicate, or unstable items, common in packaging or electronics manufacturing.

Conclusion

Both Flush Grid and Flat Top Modular Belts offer unique advantages tailored to specific industrial needs. By understanding their differences and applications, businesses can select the most appropriate conveyor solution, enhancing efficiency and product handling in their operations.

226

0

0

None

None

Comments

All Comments (0)